Used Gravure Printing Machine

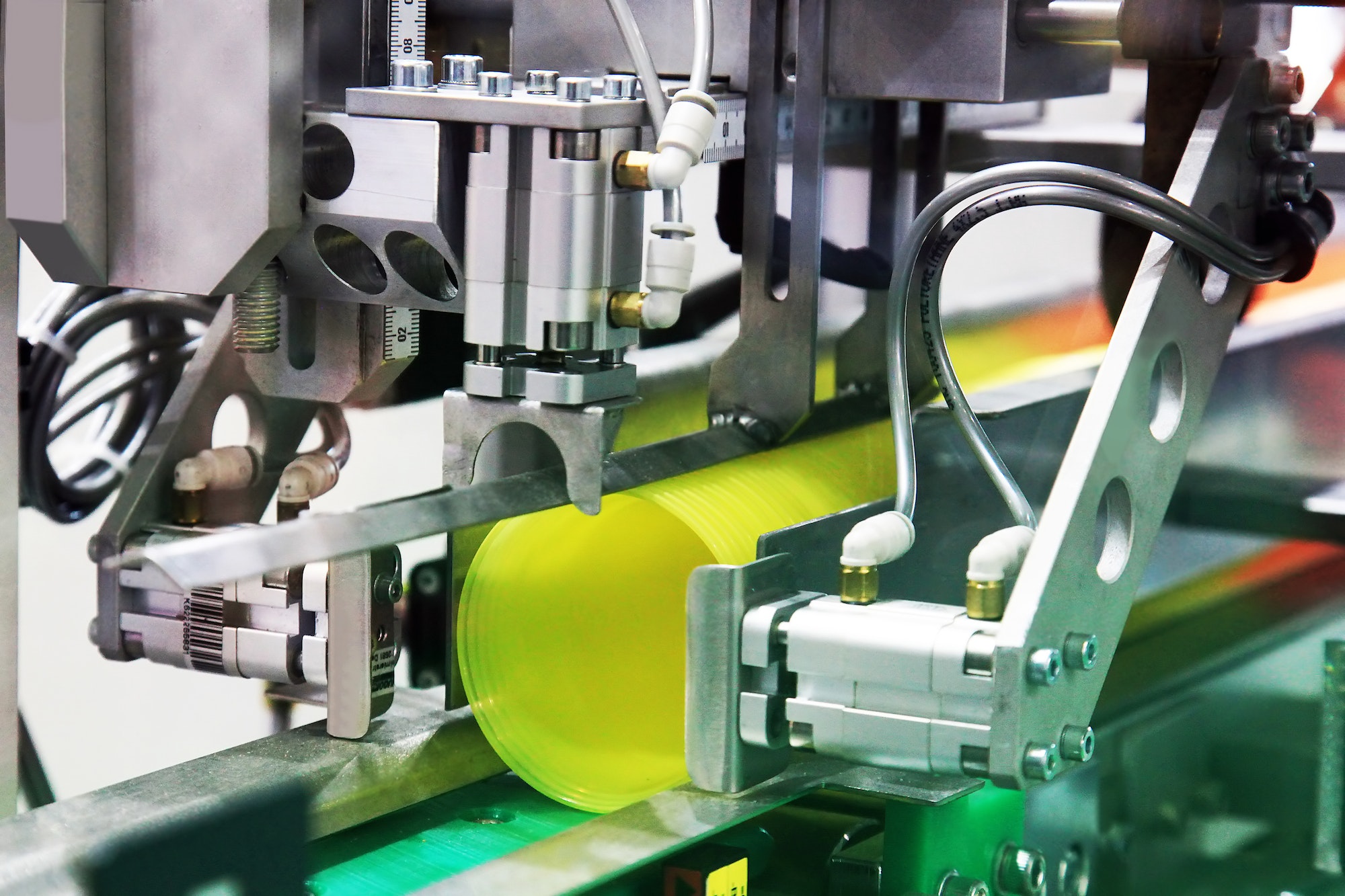

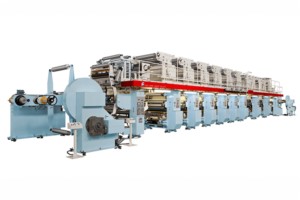

Gravure printing machines also known as rotogravure printing, it’s a high-quality printing process that utilizes engraved cylinders to transfer ink onto the printing substrate. Our used gravure printing machines are carefully inspected and refurbished to ensure optimal performance and reliability. Whether you are in the packaging, label, or flexible printing industry, our machines can meet your printing needs. Visit our website to explore our inventory and find the perfect used gravure printing machine for your business.

If you have any specific requirements or additional information you would like to include in the introduction, feel free to let me know, and I’ll be happy to assist you further!

Table Of Contents For This Page

It is not easy to introduce all aspects of USED MACHINES, so we have prepared a lot of information on this page for you to delve into. To make sure you can find the information you want quickly, we have prepared this content directory that will jump to the corresponding location when you click on it.

General Applications For Gravure Printing Machine

Used Gravure Printing machie is widely used in various industries such as publishing, packaging, and advertising. It enables businesses to produce high-quality printed materials at a lower cost, making it a valuable asset.

General Hot Selling Used Machines

Best-selling products include a range of used printing and packaging machinery, such as gravure printing machines, laminating machines, bag making machines, slitting machines. We also provide complete production lines that are designed to meet the specific needs of our customers.

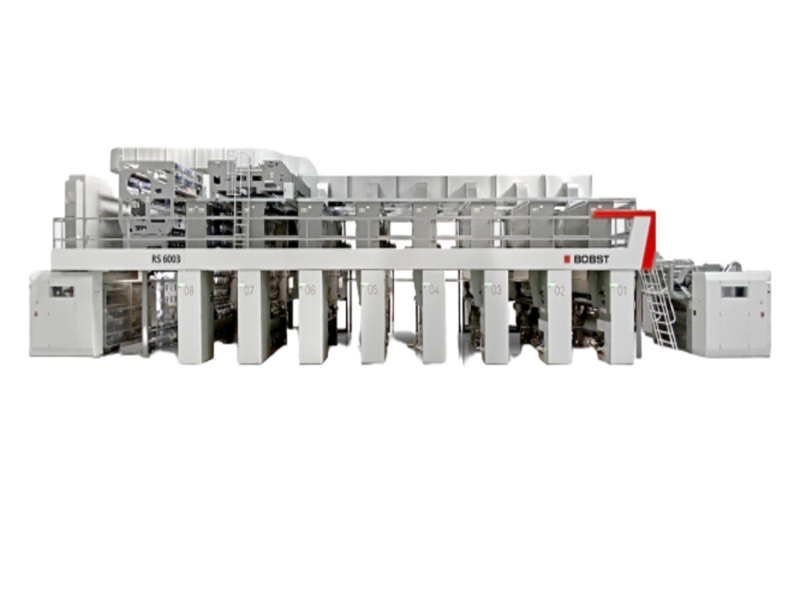

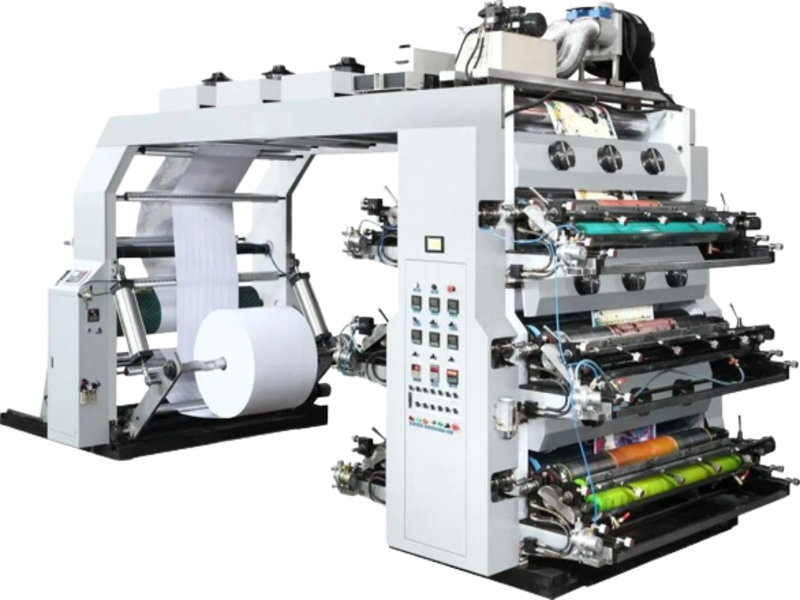

Used Rotogravure Printing Machines

- Sharp and crisp prints

- Durable and long-lasting

- Affordable printing solution

- Versatile printing capabilities

Second-hand printing machines, including gravure printing machines and electronic shaft printing machines, are available from a variety of brands such as BOBEST from Switzerland, Windmoller & Holscher from Germany, Fuji from Japan, and Beiren and Huitong from China. We can recommend the most suitable equipment based on our clients’ budget and requirements.

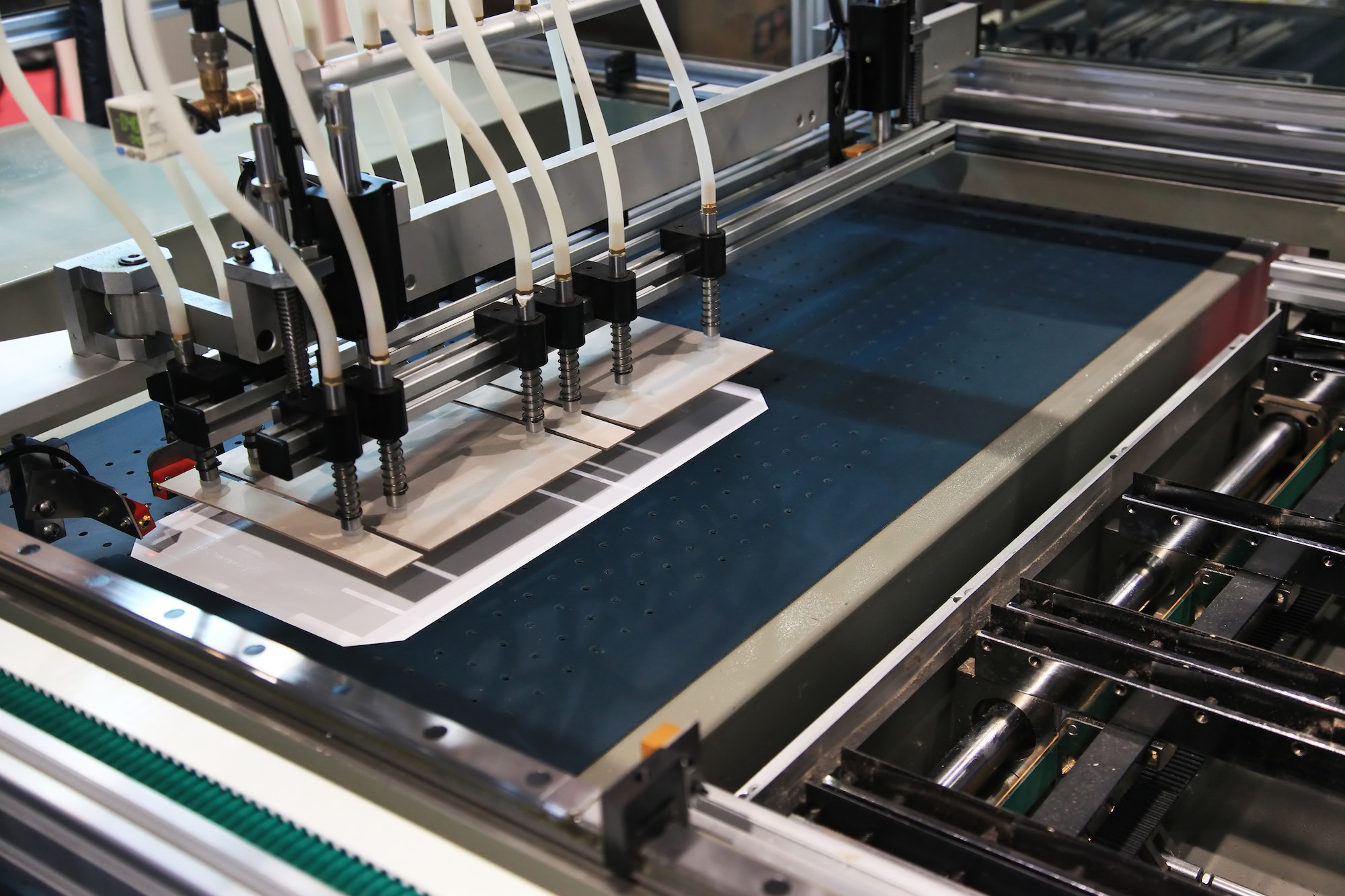

Used Solventless Lamination Machines

- Reliable equipment

- Cost-effective solution

- Compact and space-saving

- Versatile material compatibility

Second-hand laminating machines can be broadly classified into two categories: dry laminators and solventless laminators, with widths ranging from 1050mm to 1300mm. Popular brands include Nordmeccanica from Italy, Comexi from Spain, Guangzhou TongZe and BeiRen from China. All second-hand laminators are available for trial testing, ensuring you can find the right equipment for your needs.

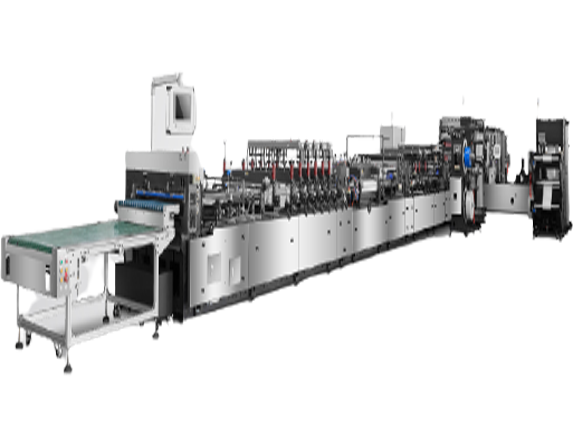

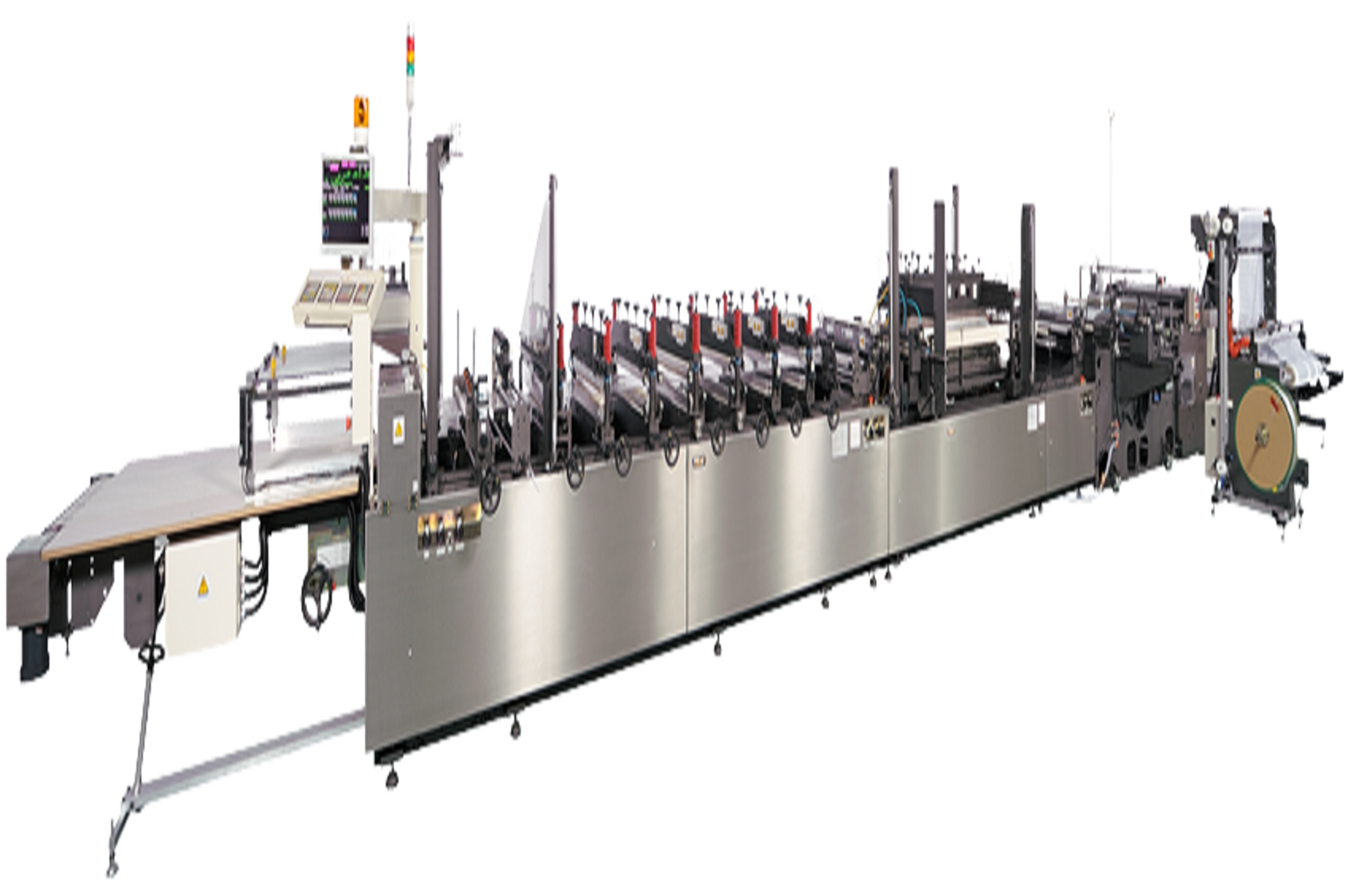

Used Bags Making Machines

- User-friendly interface

- Adjustable speed settings

- Compact and space-saving

- Low energy consumption

Used bag making machines cover a wide range of models such as three-side seal, three-side seal with zipper, stand-up pouch, stand-up pouch with zipper, bottom gusset, bottom gusset with zipper, and four-side seal machines. We carry reputable brands like TOTANI and Huitong, providing cost-effective solutions for producing high-quality bags in different sizes and shapes. These machines are versatile, energy-efficient, durable, and user-friendly, making them suitable for different production needs.

Estimated Cost Analysis For Used Machines

Please note that the final cost of used machines depends on the customization services you require, the brand and model of the equipment、the machine’s configuration、its age and wear and tear、and the distance of transportation. Taking booking used rotogravure printing machine as an example:

We provide services for dismantling and transporting equipment from the original manufacturer to a warehouse, followed by reassembly. Additionally, our engineers can provide on-site installation and debugging services overseas.

$5200 -$15000

Used equipment requires maintenance and repair, including cleaning, lubrication, and replacement of worn parts such as printing plates, ink, solvents, and replaceable components. The cost of replacement parts depends on the equipment's brand and model, as well as the pricing of the parts from suppliers.

$3000- $10600

shipping cost covers the dismantling and transportation of equipment from the original manufacturer to our warehouse, but the cost of shipping the equipment from our warehouse to overseas customers varies based on the country and port of arrival, with different fees for each port.

$2800- $12000The Process Flow & Duration Estimation

Please note that the final cost and time depends on the customized service you require, the specifications of the used machines , and the distance of transportation. Take the example of booking a flat bottom pouch machine:

Step 1: Phase time (3-7 days)

You can browse our inventory of used equipment online or in-person. Our sales representatives are available to communicate with you and recommend the most suitable options based on your needs and budget. After you have selected the equipment, we will provide further information to ensure that you have a clear understanding of the selected used equipment and its compatibility with your business.

Step 2: Maintenance and repair (within 7-10 days)

We provide maintenance and repair services for used equipment, including cleaning, lubrication, and replacement of worn parts. We also perform program upgrades or replacements based on customer requirements to meet their different needs.

Step 3: Test machines (2- 3 days)

After equipment maintenance and repair, we perform electrical connection and grounding tests to ensure the safe operation of the equipment. We also conduct operational tests to ensure all functions of the equipment are working properly. If necessary, we will adjust and calibrate the equipment to ensure it operates properly and delivers optimal performance.

Step 4: Shipping (7-10 days)

After completing the testing of the used equipment, we will arrange delivery based on the client’s requirements. Before arranging the delivery, we carefully inspect the equipment and prepare sufficient packaging and protection to ensure that the equipment does not incur damage during transportation. We choose the most suitable transportation method and logistics company to ensure that the equipment is safely delivered to the client’s designated destination. We also communicate with the client and provide timely information regarding transportation and installation to ensure that the client receives the equipment on time and can install it for use.

Want to know how to compress lead times?

To shorten the delivery time of second-hand machine, measures such as accelerating machine testing and inspection, preparing spare parts in advance, cooperating with reliable logistics companies, and communicating and coordinating with customers can be taken.

The Basic Knowledge Gravure Printing Machine

IusedMachines pleased to offer a wide selection of used gravure printing machines for your printing needs. Our used gravure printing machines are designed to deliver high-quality and precise printing results. Equipped with advanced technology and robust construction, these machines are capable of printing on various substrates such as paper, film, and flexible packaging materials.

Dry Lamination Machine & Solventless Lamination ?

Name Solventless Lamination Machine Year 2015 speed 350m/min In today’s dynamic packaging industry, lamination plays a vital role in enhancing the visual appeal, durability, and functionality of various products. Two commonly used methods for lamination

What should buyers consider when purchasing used machine?

As a buyer interested in purchasing used printing and packaging equipment, it’s natural to have concerns about the process and potential risks involved. While buying used equipment can be a cost-effective solution, it’s essential to

Gravure and Flexo Printing Machines: Which Should You Choose?

A Comprehensive Comparison Between Gravure and Flexographic Printing Machines: Which Should You Choose? Gravure vs. Flexographic Printing Machines: How to Choose? Understand Their Differences for a Smarter Decision When purchasing printing equipment, many people face

How Running Deposits Secure Top Second-Hand Printing Machines ?

Unlocking the Mystery of Running Deposits for Second-Hand Equipment In the world of second-hand printing equipment, a peculiar practice often perplexes potential customers: the requirement of a “running deposit” even after they have thoroughly inspected

Used rotogravure printing machines can work how many years?

Used rotogravure printing machines can have a long operational lifespan, often working for 15-20 years or more with proper maintenance and care. Here are some key points about the longevity of used rotogravure printing machines:

What is the price of 8 color rotogravure printing machine?

Looking to upgrade your packaging production with an 8-color rotogravure press? The price varies significantly based on several key factors that every buyer should understand. An 8-color rotogravure printing machine typically costs between $200,000 for

Used machines can exported to Indonesia?

Used machines can exported to Indonesia?Yes , it can . Exporting used printing machines to Indonesia is a significant business opportunity, but it requires close collaboration between buyers and sellers to ensure a smooth process.

Navigating the Rising Sea Freight Costs

Analysis of Rising Shipping Rates Shipping rates have been rising continuously in recent times, mainly due to the following reasons: Impact of Rising Freight Rates In summary, multiple factors such as geopolitical conflicts, the increased

Addressing Used Printing Machine Transportation Challenges

Transporting used printing equipment can present unique challenges that need to be addressed for a successful delivery. In this article, we will explore the common issues encountered during packaging and transportation and discuss strategies to

Need help with used machine after-sales for buyers?

As an international buyer, purchasing used equipment can raise concerns regarding post-purchase installation and after-sales maintenance. Ensuring a smooth installation process and having access to reliable maintenance services are crucial for a successful purchase.

The Common Pitfalls When Purchasing

When acquiring a second-hand gravure printing machine, it is essential to meticulously evaluate its degree of wear and tear, maintenance history, electrical components, brand and model selection, after-sales support, and safety measures. These aspects significantly impact the machine’s performance and reliability, and they require a comprehensive assessment to ensure optimal outcomes.

- Wear and tear

- After-sales service

- Machine's electrical system

- Machine's brand and model

- History and maintenance records

This information can help determine the machine’s wear and tear and maintenance status.Knowing the machine’s maintenance and after-sales service, such as service scope, maintenance cycle, and cost, can ensure the machine’s normal use and support.

If the machine’s maintenance and after-sales service are not adequate, it may result in delayed repairs and maintenance, which could impact production.It is also advisable to purchase from a reputable used bag making machine dealer with good after-sales service to facilitate future maintenance and support!

When purchasing a used machine, it is important to carefully inspect the machine’s wear and tear, know its history and maintenance records, check the electrical system, choose the appropriate brand and model, and consider the machine’s after-sales service and safety issues.

Only by fully considering these factors can one purchase a used flat bottom pouch machine that is stable in performance and reliable in quality!

A Brief Self-Nomination, Why Choose Iusedmachine?

We specializing in the second-hand printing equipment in China, with over 10 years of experience and technical accumulation. Our warehouse covers an area of 8,000 square meters and stores a large quantity of second-hand printing equipment, covering multiple brands and models to meet the needs of different customers.

At the same time, we attach great importance to after-sales service. We have a professional after-sales service team that can provide fast technical support and solutions. We conduct comprehensive inspections and maintenance before sales to ensure that the machines are in good working condition.

- Wide selection of reputable brands.

- Experienced and knowledgeable team.

- Competitive pricing for high-quality equipment.

- Comprehensive services including installation and after-sales support.

- Global reach and reputation as a trusted provider of used printing equipment.

At our company, we offer high-quality used printing equipment, competitive pricing, comprehensive services, and expert guidance from our experienced team of professionals. With a global reputation for excellence, we are dedicated to helping our customers succeed in their printing business. Choose us for your used printing equipment needs and experience the difference that our commitment to customer satisfaction can make.

The FAQs About Gravure Printing Machine

As a customer considering the purchase of a second-hand Gravure Printing machine, you must be have many questions and concerns that come to mind.Some of the main questions may include the condition of the machine, its working performance, and the level of maintenance it has received.

Can the used machine produce high-quality prints consistently?

Our used gravure printing machines are carefully tested to ensure they deliver consistent and excellent print quality. We check for ink adhesion, color consistency, and precise registration to meet your printing standards.

Are there any limitations regarding the materials it can print on?

Our used gravure printing machines are designed to handle various substrates, including paper, film, and flexible packaging materials. They are compatible with different inks and coatings, allowing you to print on a wide range of materials.

Is there reliable technical support if any issues arise?

We ensure the availability of spare parts for our used gravure printing machines. Our experienced technical support team is ready to assist you and provide prompt solutions. We can also connect you with qualified technicians for maintenance and repairs if needed.

How does the cost of a used machine compare to a new one?

Purchasing a used gravure printing machine offers significant cost savings compared to buying a new one. Our used machines provide excellent print quality and performance, ensuring a favorable return on investment. The lifespan and productivity of the machine depend on proper maintenance and usage, but we ensure that our machines have a long service life and reliable productivity.

Is it compatible with industry standards and future advancements?

Our used gravure printing machines are designed to be upgradable and adaptable. They can be retrofitted with modern features and technologies to keep up with industry advancements. They are built to support evolving printing requirements and market demands, ensuring long-term usability and competitiveness.

How can we ensure our operators become proficient in operating the used machine?

We offer comprehensive training programs for operators to ensure they are proficient in operating and maintaining our used gravure printing machines. Our training covers machine operation, maintenance, and optimization techniques. We provide guidance and support to help your operators maximize machine performance and efficiency.